13 Dec 2014: Final Revision 3.2 CAD/CAM Layout

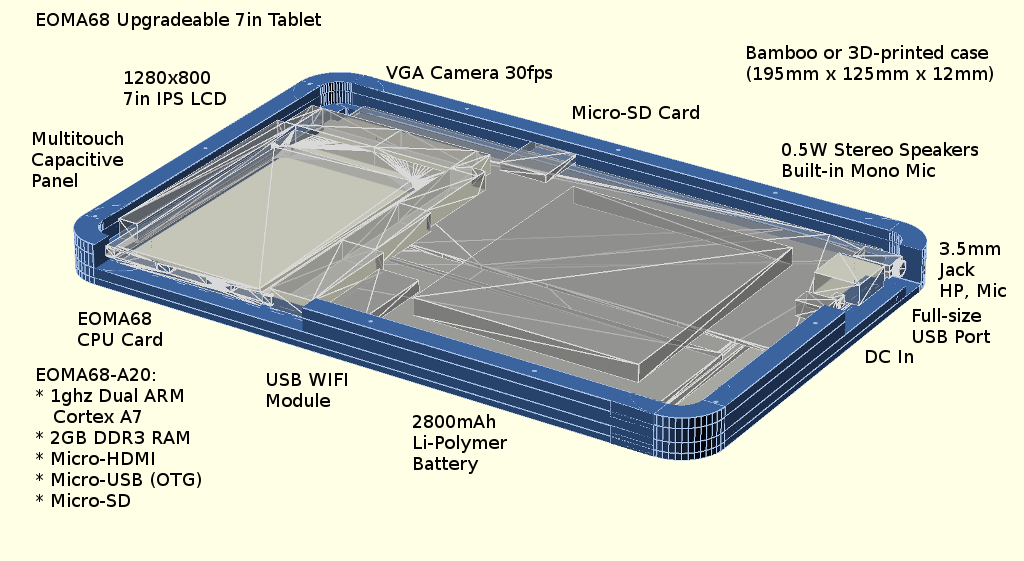

After noting that the LCD is deeper, the camera was found to be covered up and had to be moved to the top left corner, entirely out of the way of the LCD. This tends to be the primary reason why cameras are in the top corner of tablets: the layout in other locations is almost impossible. With that as another inviolate requirement, the rest of the layout falls into place and is now considered final.

Top left is the VGA camera. Along the top edge is the tablet's MicroSD card slot. Along the right edge from top to bottom is the 3.5mm Headphone Jack (including stereo headphones and microphone), followed by a full-sized USB Host port, then the power/reset button and then the DC power jack. The CPU Card slots into the bottom left corner along the front edge, as this allows the battery to take up the majority of the right-hand side whilst leaving the LCD's taped-down LVDS Converter PCB completely clear.

Battery-wise EEMB have a standard-sized battery at 68.5mm x 89mm x 5.3mm which works out to a 2800mAh capacity. There is however space for larger batteries (up to approximately 85mm x 100mm x 6.3mm) which would give more than a 50% increase in capacity to around 4500mAh, however it would require a custom order from EEMB which has a MOQ requirement so is not being immediately considered.

Casework-wise, the layers stack up to between 12mm and 14mm depending on the chosen thickness and material of the top and bottom layers. Wooden laminates throughout would require a 14mm thickness, whereas if stainless steel is chosen for the base then a 12.1mm thickness would be feasible, as long as a cover arrangement could be made to ensure that the sharp edge of the stainless steel is not exposed. Possible solutions there involve filling in the holes with acrylic, which, around the Power, USB and Headphone sockets is likely to be needed anyway as the power and charging LEDs shine through from just behind the power button. It's rough, it's 3D printable, the parts can be 3D printer be laser-cut from any material and stacked without gluing, and it's workable, so we go with it.